Tire Service: Mobile Tire Service Guide

Introduction

Acting as the only point of contact to the road a vehicles tires — frequently taken for granted– are the first checkpoint to road safety. In a nutshell, tires affect a vehicle’s handling, braking, and overall road safety to themselves and other travelers. To obtain the required performance for safe traveling, a vehicles tires must obtain proper maintenance and inspection, meaning they must have adequate: tire tread depth, tire air pressure, tire balance, wheel alignment, and a followed balanced torque mounting practices.

Although tire maintenance can be regarded as a “Do It Yourself” type of job. There are several tire maintenance procedures that only automotive repair professionals with special tools/machines and knowledge should handle. However, we can explain the procedures that can be done on your own.

Do It Yourself Tire Services

Preventative Tire Maintenance

Properly checking your tires on a daily/weekly basis is key to protecting you and your vehicle’s safety. Although often overlooked, most vehicle owners should conduct tire inspections weekly, this is acceptable in the non-winter months. However, if your commute involves facing off against potholes or drive long distances regularly, then you should inspect your tires more often. This is especially true for the winter months; in which winter tire pressure can change rapidly. Staying on-top of the ever changing factors require observational some diligence.

Observational Tire Maintenance

National Highway and Traffic Safety suggests, you should always give your tires a quick glance before heading out on the road. With just a quick once over you can save yourself hundreds of dollars and even save a life by taking the precautionary measures. By performing these inspections and building a routine, you give yourself the ability to detect issues such as tire pressure and tread wear. Being able to detect things like a puncture in your tire, allows a quick fix-and-plug before it becomes an expensive issue. Additionally, by observing your tires treads you can get a good indication if your tires are wearing properly. Even wear of tires are essential to prolonging its life, uneven tread-ware can cause poor handling blow-outs and accidents.

Driving Concerns with Tires

Unusual vibration or thumping noise usually indicates an out-of-balance tire, one with tread that has a flat spot due to locking the wheels in a panic stop, or a tire with a separated belt.

While driving at a steady speed, feeling a pull to one side may indicate an under-inflated or damaged tire on the side of the car to which the vehicle pulls. If this is not the case, a brake problem or poor wheel alignment may be causing the pull.

Tire Pressure

When it comes to finding the correct tire pressure for your vehicle’s tires, there will typically be two locations in which you can obtain it from: Driver side door-jam sticker, or the outer-sidewall of your tires – beneath the manufacturer brand name.

Recommended pressure is usually between 30 and 35 PSI. Pounds per Square Inch indicates the minimum amount of air pressure needed to support your vehicle maximum load-carrying capacity. Under inflated tires will see poor fuel economy and handling as well as premature wear from too much flexing and tire overloading.

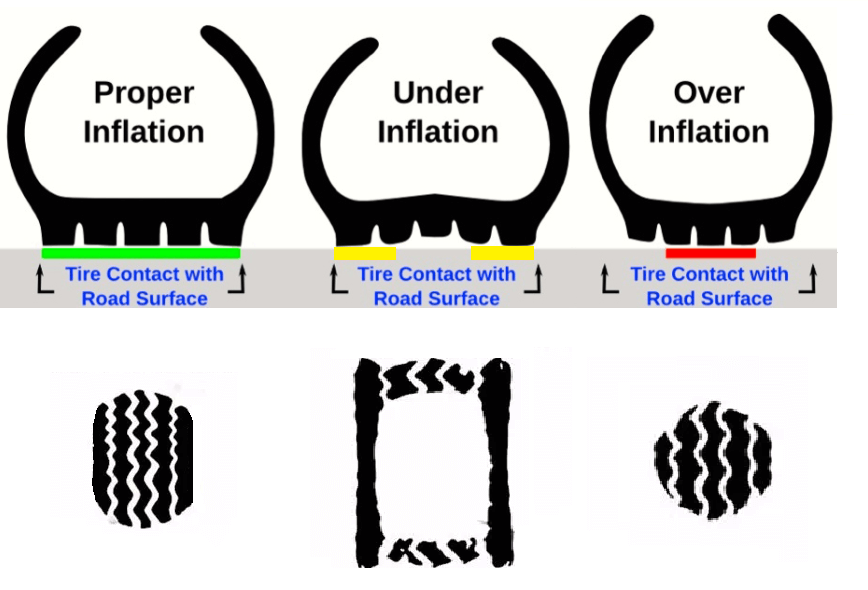

When’s the best time to check your tire pressure? A few good rules of thumb are every time you fill up for gas, every 10 degree change in temperature, or every 30 days. The three most common types of tire wear are proper inflation (even tread wear), under inflation (outer-tread wear), and over inflation (inner-tread wear).

Proper inflation: Properly inflated tires will have an equal distribution of tire tread contact with the road. This creates evenly distributed wear for the entire tire, allowing a smoother and safer ride.

Under inflation: Under inflated tires are caused by having little air pressure, which affects the outer tread edges, making them the only contact the road. This creates wear primarily on both edges of the tire tread, with less wear in the center.

Over inflation: Overly inflated tires are caused by having too much air pressure, this directly affects the tire’s middle section, being the only point of contact to the road. This creates wear primarily in the center of the tread, with less wear at the tire’s edges.

Signs of Tire Wear

Poor tire maintenance can lead to premature tire wear, a flat tire or even a blowout. Factors other than tires themselves also can affect tire wear. Worn suspension parts and an improper wheel alignment both play a direct role in tire wear and performance.

Proper tire maintenance checklist suggest worn suspension components should be replaced every 40,000 miles. While a vehicles tires should be checked anytime steering feels abnormal or every month.

Tire Tread Wear Pattern Explanations

Tread wear on one edge of the tire: This typically occurs when the wheels are out of alignment.

Erratic tread wear can be one of two things:

- A suspension component’s integrity (the shock absorbers) has more than likely failed and will need to be replaced.

- Tire cupping means a wheel(s) is out of balance.

Raised portion of the tread or sidewall: May indicate that one of the belts in the tire carcass has separated from those next to it.

Tire Tread Inspection

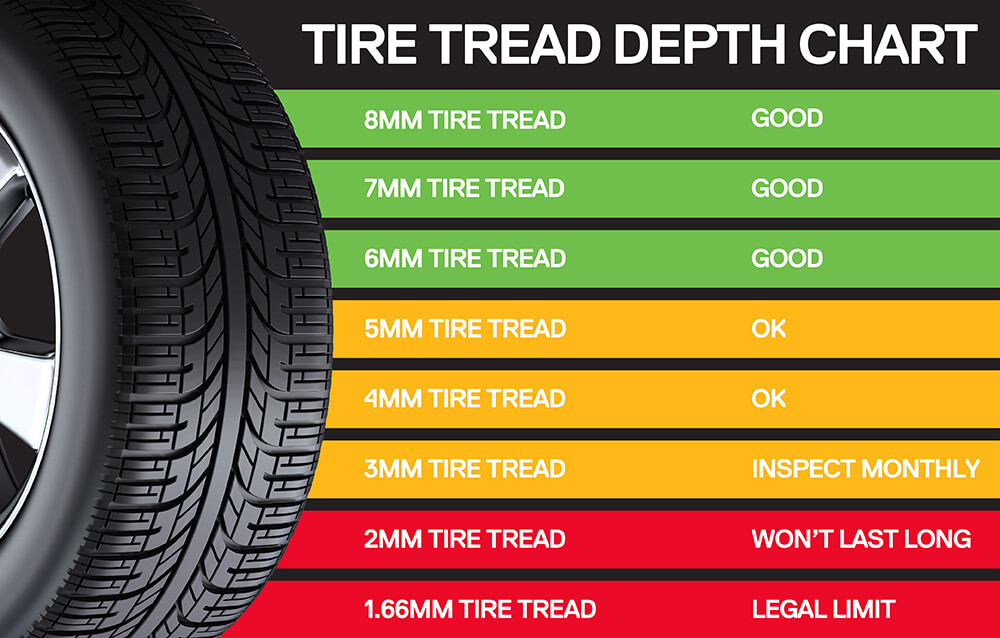

Tire performance strongly depends on good tread condition, meaning it is necessary to have adequate tread depth to maintain optimal traction on wet roads. Tire tread should be checked at least once a month for excessive and uneven wear. There are ways you can get a good indication of you tire tread health:

- Tread Depth Gauge

- The Traditional Penny Test

- The Quarter Test

Tread Depth Gauge: How to Use (5-Steps)

If you have a tread depth gauge handy, this tool will give you the most accurate tread depth measurements. If you don’t have a Tire Tread Depth gauge — you can skip to the Quarter Test or Penny Test — they can easily be purchased from any auto-parts store. Here is the five-step process to do it the right way:

- Make sure the gauge is zeroed-out on a flat surface. You might be able to adjust the pin to get an actual reading of 0/32″.

- In the air, push the measuring scale all the way in, so the measuring pin sticks out as far as possible.

- Place the measuring pin in the main tread groove, and press down until the base of the gauge is resting firmly on the tread blocks on either side of the groove.

- Carefully pull the tread depth gauge away from the tire, and read the measurement shown on the scale.

- Depending on where you started on the tire repeat steps 1–4 for the outer edge, center and inside edge.

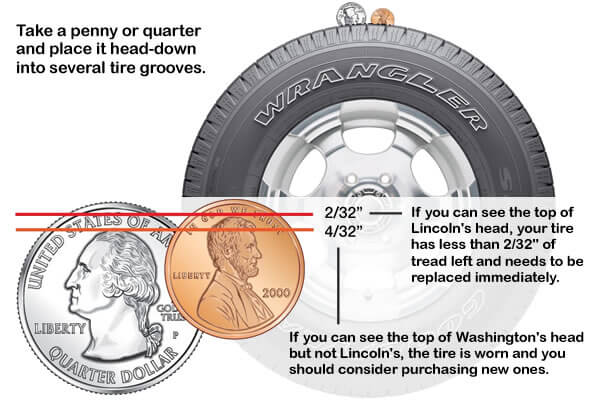

The Quarter Test (Washington Test)

*This test will require a quarter!

To get an effective read of your overall tire tread health, take measurements in three locations: (1) outer edge, (2) center, and (3) inside edge.

Have the top of George Washington’s head facing down. Hold the Quarter between your thumb and index finger and insert it into a tire’s tread groove; If the top of Washington’s head is not visible, your tires have at least 1/8” of tread and are fine for continued use. If you can see above the top of Washington’s head, it is time to start shopping for new tires.

The Penny Test (Lincoln Test)

*This test will require a penny!

The penny test is done in the same way, except that if you can see above the top of Lincoln’s head your tires have less than 2/32” of tread, which is below the legal minimum and cause for immediate replacement. Tires worn to this level will also have visible wear indicators (thin bald strips) running from side to side across two or more tread segments.

The difference between 1/8” and 1/16” of tread depth might not seem like much, but based on research by the Tire Rack, America’s largest independent tire research group the difference is significant. Their example uses a pickup truck traveling at 70 miles per hour that passes the penny test can take up to 499.5 feet to stop on wet pavement. However, the same truck has a stopping distance of 377 feet, that’s 122 feet less— the equivalent of Six car lengths, and a 24% difference in braking distance — shorter if it passes the quarter test instead.

The Tire Rack also reported that tires passing the quarter test exhibited better grip on the road under other driving conditions as well. Given these facts, we recommend that you use a quarter to check tire wear and determine when it is time for replacement.

Plugging a Tire

If you’ve got a flat tire due to a puncture, you may be able to save money by repairing it with a DIY tire plug kit instead of buying a new tire; Plugging a tire is a simple and inexpensive repair that only takes about 15 minutes.

First, we must identify where the puncture is located, any puncture in the sidewall is regarded as unpluggable. Plugging a sidewall can result in a blowout, according to the National Highway Traffic Safety Administration.

Now if the puncture isn’t located in the side wall, you may plug the puncture using a tire repair kit. These are easily obtainable at any store that sells auto maintenance supplies — the price should be less than $15.

5 Steps How to Plug a Tire

- Before you remove the puncturing object lodged into your tire, we suggest taking a piece of tape placing it just below the spot where it punctured the tire. Additionally, you’re going to mark the exact spot on the tape with a pen (marker works best). This insures that you will be able to find the puncture sight again.

- Make sure the tire is on a flat-stable surface when you do this. You will more than likely require a tool to get enough grip on the object – a set of pliers will provide proper leverage for the object: Go ahead and remove the puncturing object. Afterwards fetch a tool within your tire plug repair kit, that looks like a rounded file with a handle. Its purpose is to “round out” and clean up the puncture hole in your tire. By inserting the rounded file into the incision, carefully file any excess debris to prep a clean plug seal.

- Also, in the tire-repair kit there are these adhesive based “worm-like” pieces known as worm-plug. After unwrapping the worm-plug, thread it through giant needle tool and center the worm-plug on the plugging tool. Now we must insert the worm seal into the puncture. This will require pressure so that the tool and the plug sink into the hole until only about a half-inch is sticking out.

- At this point we need to pull the plugging tool straight out; Note the plug stays where it’s supposed to be. If you have something to cut the ends of the plug off trim, it close to the tire. If nothing’s handy, you can trim it later.

- Lastly, fill your tire with air to the proper tire pressure and remount it. If you haven’t had your tires rotated and balanced in a while, this might be a good time to visit your local mechanic and do so. It will extend the life of your tires.

The Importance of Tire Rotations

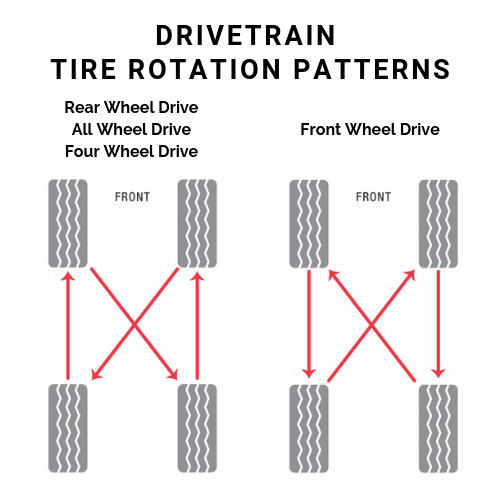

The tire rotation process is the practice of alternating the wheels (tires and all) of a vehicle from one position to another; This allows/ensures evenly distributed tire tread wear. Even tire wear is desirable to extend the use-life of a set of tires. Tire tread size is very important when it comes to traction if the tread design is worn out you may face problems. As we know with drivetrain weight distribution, the weight on the front and rear axles will often differ which causes uneven wear.

Majority of vehicles have their engine in the front, therefore their front-set of tires will bare more weight than the rear tires. Front-wheel drive vehicles have the engine along with the trans-axle in front, adding to the weight differential. Moreover, additional stress is placed disproportionately on the front tires by braking and steering. Thus, tire rotations need to occur more frequently for front-wheel drive vehicles.

To gain maximum life and performance from your tires, it is essential to rotate your vehicle’s tires. Refer to your vehicle’s owner’s manual for mileage recommendations. Usually tire rotation is performed between 5,000 and 7,000 miles. Common on performance cars are tires designed to rotate in a specific direction; these can only be rotated front-to-rear, and if different tire sizes are used on the front and rear axles rotation is not possible.

Leave it to the Professional Tire Services

The following processes should only be done by professional licenses automotive service centers. All of these services require special tools to effectively get the procedure done. These remaining services are to be left to professionals.

- Tire balancing

- Torque tightening

- Wheel alignment

- Removing tire from the rim & replacing tire on the rim

- Setting the tire bead

Tire Balancing

Properly balanced tires minimize uneven wear and have an extended overall life-span. Tire balancing should be left up to professional services who own a Tire balancing machine. Tire Balancing Machines are rather simple to use machines — How to balance a tire — but they’re unrealistically expensive to own, unless you’re in the auto shop industry.

A correctly balanced wheel will have small weights attached to the rim – wheel weighs limit vibrations of the tire and wheels as they turn. Generally, brand new installed wheels SHOULD have already been balanced, and thereafter whenever a vibration is noticed tire maintenance is needed. Tire Balancing is needed whenever a tire is removed from the wheel. This is due to tire tread wear from consistent use, or if the tire weights feel off or shifted.

Torque Tightening

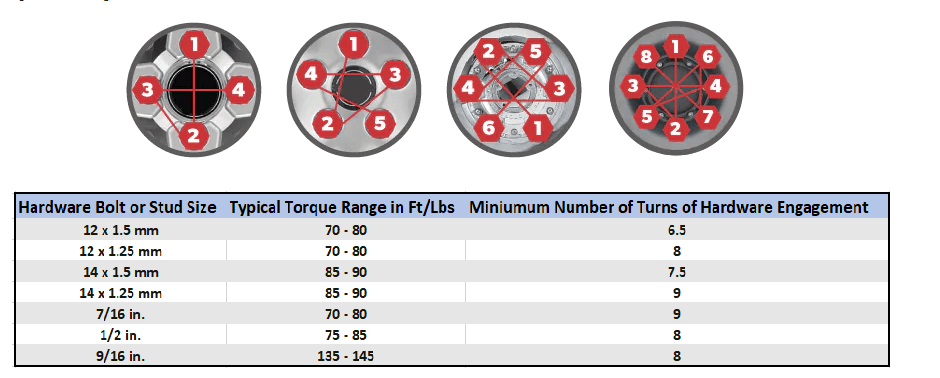

When it comes to having “proper wheel installation” this refers to the wheel-mounting hardware known as “lug nuts and lug bolts.” These fasteners must be tightened to the recommended torque specification for the vehicle make, model, and year. Torque specifications are usually found in the vehicle’s owner’s manual.

Achieving the proper lug nut torque requires using the correct tools, procedures, and patterns. These will prevent over-tightening the hardware, stripping the fastener threads, and stretching the studs. It will also reduce the possibility of warping the brake drums, rotors or hubs.

Wheel Alignment

Having a wheel alignment or tire alignment is the measuring process for of each individual wheel position. Once the measurements are gathered, they are then compared to the manufacturer specification – each vehicle has its own specific wheel alignment configurations. In the instance of any alignment measurement being outside the specified range vehicle handling will be affected, along with fuel economy efficiency, and finally uneven tire wear.

In the event of having new tires installed you should have the wheel alignment checked and adjusted. As well as, anytime unusual steering characteristics are observed. When a vehicle’s wheels are properly aligned the car will drive down the road in a straight line without drifting or pulling to either side. A drift or pull can be caused by problems other than just alignment, so getting a thorough inspection by a qualified shop would determine the exact nature of the problem before an alignment is performed.

We stressed the importance of a vehicle’s tires, so is essential to obtain the required performance for safe traveling. A vehicles tires must obtain proper maintenance and inspection, meaning they must have: tire tread depth, tire air pressure, tire balance, wheel alignment, and a followed balanced torque mounting practices. We at DriveSmart aim help you be more proactive when it comes to giving your car the care it deserves. By spending a few minutes conducting observational maintenance every day, you can help protect your family, improve your vehicle’s performance, and lengthen the life of your automotive investment. We can also help pay for any tired related services that are to be left to the professional with our Ultimate® Savers Club.

"> /var/www/dsw/wp-content/themes/DriveSmart_2024_v1.1/pillars/mobile-tire-service-guide/index.php on line 214

">

"> /var/www/dsw/wp-content/themes/DriveSmart_2024_v1.1/includes/quote-modal.php on line 8

">